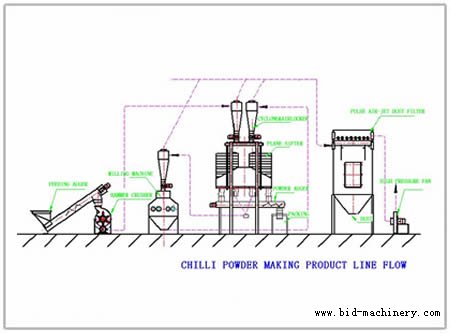

CHILLI POWDER MAKING PRODUCT LINE (CHILLI GRINDING)

Our factory developed a new product line, BLJ-18 chilli (pepper) processing line, which adopts crushing, screening, dust collection and other processes to get powder, grits. Mainly used to make pepper grits, powder, also can be processed dehydrated garlic, carrots, onions and various spices, and for chemical, pharmaceutical, food processing industries.

1. Main features:

The line has features of completed automation, easy operation, low labor intensity, low power consumption and high production. Process is divided into coarse crushing, fine crushing. Crushing material by rollers, will not change chili powder, grits color by high temperature during grinding.

The line uses pneumatic force to transport materials. Good air proof and pulse dust filter can improve the working condition without irritant smell and dust. It is the ideal equipment for chilli processing.

The line using quantitative auger feeding, this can adjust the feed speed by frequency conversion. Raw material goes into coarse crushing machine and crushed by rotating hammer, crushed material passing through sifter and transfer to grinding machine by pneumatic lift, after grinding material goes to sifter screened by granularity then coarse and fine powder will be resent to different milling machine and grinding and sieving again to get finished powder.

2.Main technical parameters:

Model: BLJ-18

Capacity: 16-20T/24h

Roller lenth:400mm*4=1600mm

Sieve area: 13 M2

Power: 43.5KW

Space requirement: 7M×7M

Working shop dimension: 12M×8M×8M